◆ Designed as per GMP standards, the workshops of vulcanization, die cutting, washing and packaging are up to the relative cleanness classes.

◆ Quality mangement system established and consummated as per GMP standards.

◆ Automatic pre-forming and slice cutting process is adopted.

Product Description

|

Product Name |

bromobutyl rubber stopper |

|

Usage |

Lantibiotics, injection, infusion, oral solution or other packaging |

|

Marerial |

Bromo-butyl(BIIR) |

|

Raw material source |

ExxonMobil Chemical |

|

Sterilization method |

Ethylene Oxide(EO) |

|

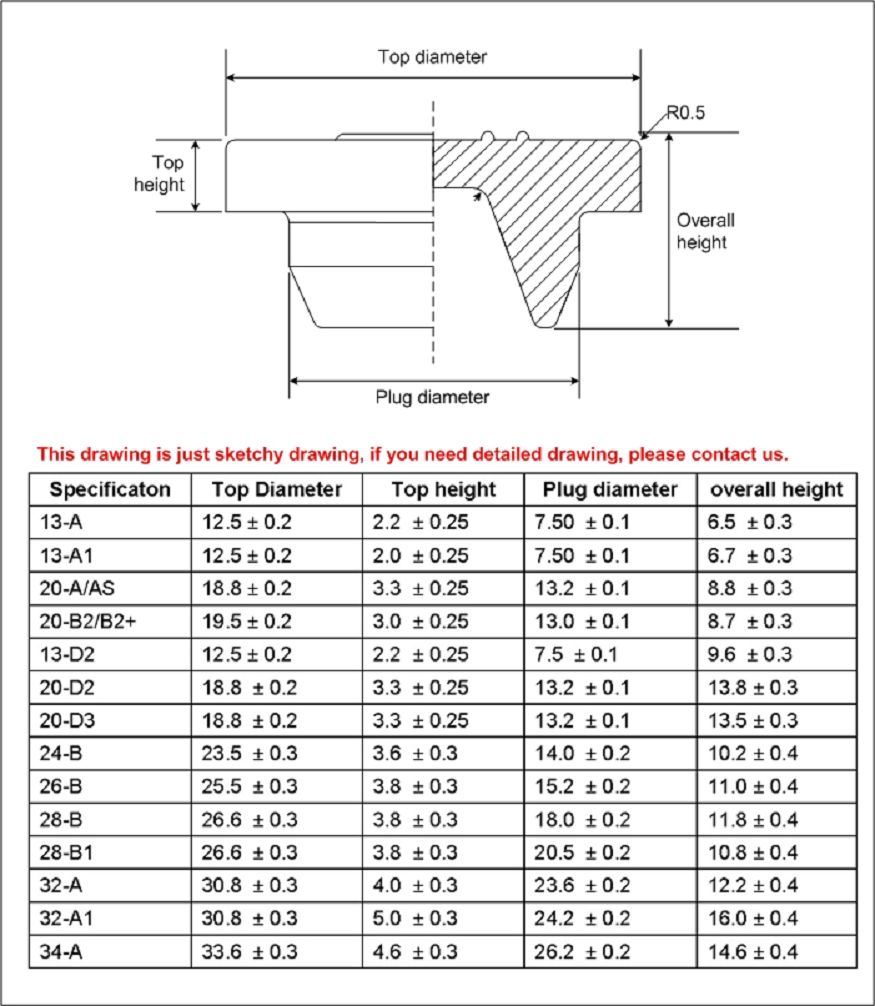

Logo and sizes |

can be customized |

|

Colorful stopper |

any color can be customized |

|

Characterization |

Odorless, airproof, stabilized chemical properties |

|

MOQ of normal stopper |

10000pcs |

|

MOQ of special stopper |

500,000pcs |

|

Productivity |

2 million pieces per day |

|

Workshop |

100-100000 class cleaning workshop meets the GMP standard |

|

Sample and courier fee |

free |

|

Inner packaging |

PE bag or RFS bag (Tyvek bag) |

|

Outside packaging |

5 layers strong corrugated carton |

|

Pallet packaging |

Be offered |

|

Payment terms |

L/C, D/A, D/P, T/T, Western Union, MoneyGram, ESCROW, e-Credit Line. |

|

Certificates |

CE, ISO9001, ISO14001, ISO15378, SFDA |

Product Features

◆ Designed as per GMP standards, the workshops of vulcanization, die cutting, washing and packaging are up to the relative cleanness classes.

◆ Quality mangement system established and consummated as per GMP standards.

◆ Automatic pre-forming and slice cutting process is adopted.

◆ Advanced full automatic vacuum making vulcanization process is adopted.

◆ Aubomatic stopper washing production line with powerful vibrating and blwing washing functions.

◆ No lefteover,international biological testing standard for biosafety and chemical

demand, cleanesand hardness, sealability.

◆ Successful compatibility test for rubber stoppers and medicine.

◆ No lefteover, international biological testing standard for biosafety and chemical demand, cleaness and hardness,sealability.

ADD: ROOM 1422,NO.5 BUILDING,NO.616,YUNFEI ROAD,NINGBO,CHIAN

TEL: +86-574-87792176

E-MAIL: sales@nb-asic.com